FULLY AUTOMATIC PNEUMATIC TILE-BACK TIRE CHANGER

Larger working size and stronger bead breaking force, perfectly meet customer requirements, with high proficiency. Various optional accessories offer unlimited possibilities for easy and safe tire services.

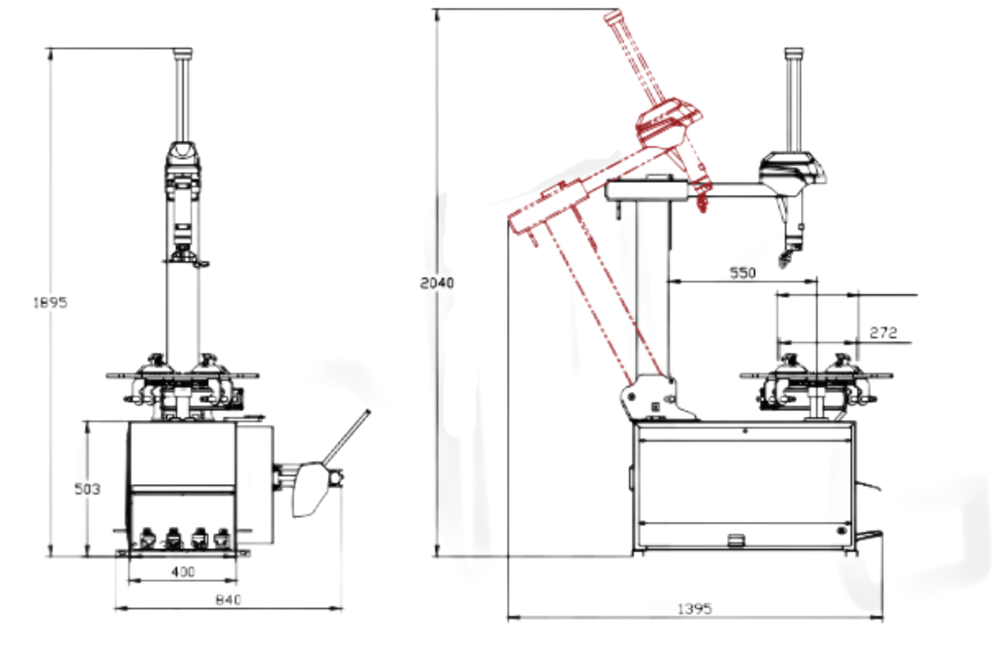

1. Fully automatic tire changer, adopts tilt-back structure. Tilt back and forth are controlled and locked pneumatically.

2. The demount head is made of high-quality alloy steel, with high strength and more durable. Equipped as standard with complete mount/demount head protectors.

3. Thickened metal hex bar, able to handle all kinds of run-flat and low-profile tires with beautiful shape, strong and durable, needs no after-sales service.

4. Reinforced cabinet design with thick plates, larger working size and powerful bead breaking force, further enhance product performance.

5. Standard aluminum housing motor, with stronger power, and stable working capacity. Equipped as standard with a digital inflating gun, and all-aluminum pedal assembly.

6. Standard 26'' turntable (28'' optional) with one-piece cast jaws, increases working strength. The turntable is made of special steel plates, not easy to deform.

7. Four-angle adjustable pressing shovel saves labor for tire pressing. Thickened shovel arm with quality shovel protective cover, and anti-skid bead breaker buffer.

8. Optional rear air tank serves tubeless tire inflation device.

| Motor power: | 0.75kw/1.1kw |

| Power supply: | 110V/220V/380V |

| Max. wheel diameter: | 1100mm |

| Rim width: | 3''-16'' |

| Inside clamping: | 13''-26'' |

| Outside clamping: | 12''-24'' |

| Air supply: | 8-10bar |

| Bead breaker force: | 2500kg |

| Noise level: | ≤70dB |

| N/G weight: | 175/192kg |

| Package size: | 1000*800*950mm |